Careers at Addison Precision Manufacturing

Driven By Precision. Defined By People.

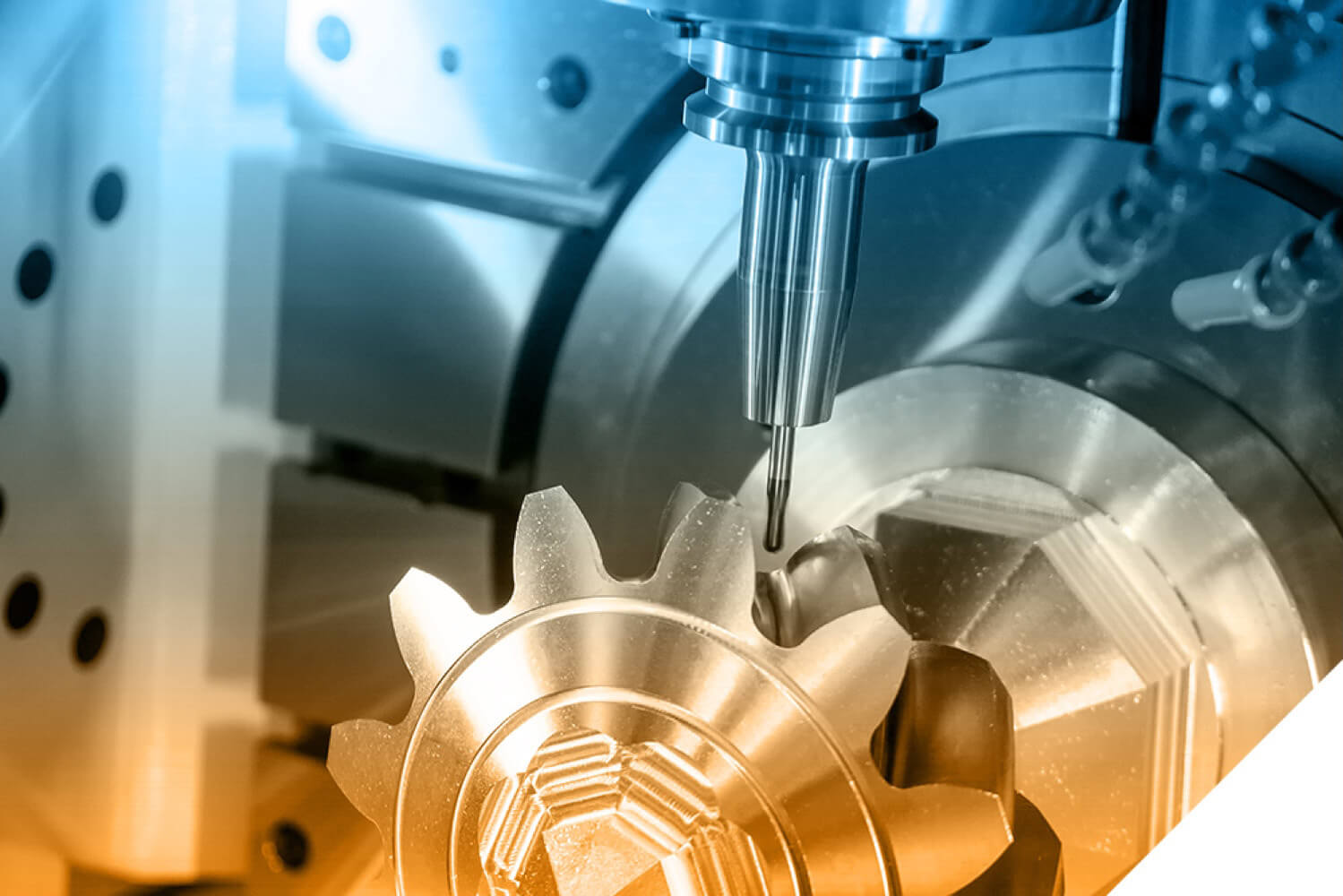

At Addison Precision Manufacturing, we’re committed to delivering precision + value + on-time delivery for complex, close-tolerance machined components in aerospace, medical, precision manufacturing and other advanced industries.

Our team leverages the latest multi-axis milling, turning, CNC grinding, Swiss-turning and EDM technologies to meet the highest standards of quality and performance.

PRECISION, PERFORMANCE, AND PEOPLE. MEASURED IN RESULTS.

70+ Years

Delivering precision manufacturing excellence since 1952.

100+ Employees

Delivering precision manufacturing excellence since 1952.

100,000+ sq. ft.

State-of-the-art facility equipped for complex machining and assembly.

Whether you’re refining a process, mentoring a teammate, or helping bring a complex design to life, you’ll be part of an environment that values both the craft and the craftsman.

Life At Addison Precision Manufacturing

At Addison Precision Manufacturing, our people are the driving force behind every achievement. We take pride in building a workplace where precision, integrity, and innovation aren’t just values, they’re part of our everyday work.

COLLABORATIVE ENVIRONMENT

We encourage cross-functional interaction between machinists, programmers, engineers and quality professionals so that knowledge flows and innovation thrives.

CUTTING-EDGE TECHNOLOGY

Work with advanced equipment and processes that push the limits of what’s possible. At Addison, precision meets innovation in every project we take on.

HANDS-ON LEARNING

From multi-axis setups to ultra-precision grinding, you’ll work with advanced machinery and systems. Addison supports training, certifications, skill development and internal career mobility.

BENEFITS DESIGNED FOR BALANCE AND GROWTH

![]()

401(k) Retirement Plan

Build your future with our company-matched 401(k) program, designed to help you save more for retirement.

![]()

Tuition Reimbursement

Further your education and skills with tuition assistance for job-related courses and certifications.

![]()

Medical

Access comprehensive health insurance plans, including medical, prescription, and mental health benefits.

![]()

Paid Time Off

Recharge with generous vacation, personal, and sick days— plus company holidays.

![]()

Dental/Vision Care

Keep your smile and sight sharp with our full dental and vision insurance plans.

YOUR CAREER DESTINATION IN PRECISION MANUFACTURING

Whether you’re an experienced machinist, a quality specialist, a CNC programmer, an engineer or a support professional, Addison is a place where your skills matter and your growth is encouraged. Our environment is fast-paced yet supportive, demanding yet rewarding. If you thrive on precision, challenge and continuous improvement, Addison is for you.